What effect does the shipping of books have on the environment?

Over 90% of the world’s cargo moves by sea, and the freight industry is acutely aware of the impact it has on the environment. International shipping is responsible for 2.1% of all Carbon Dioxide emissions, and the Sulphur Oxide output from the 15 largest container ships is more that all of the cars in the world. However, shipping by sea remains the most environmentally friendly method.

Road or Sea?

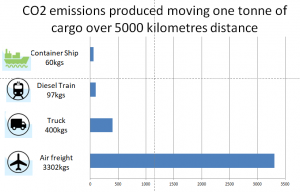

It goes without saying that airfreighting books, apart from the huge expense, produces the greatest output of CO2. However, many publishers are faced with the option of printing in Europe or Asia, and wonder which is the better option.

Moving a 40’ container of books weighing 18 tonnes door to door from factory in Shenzhen, China to Warehouse, Oxford by sea would generate approximately 1.17 tonnes of carbon. The same cargo moving by truck from Milan, Italy to Oxford would generate over 1.3 metric tonnes and from Bratislava, Slovakia it would be over 1.53 metric tonnes. In both cases, the transport cost would be far higher than the movement by sea.

What is the Shipping Industry doing to improve its impact?

The International Maritime Organisation (IMO) has set a target to reduce CO2 emissions by 50% by the year 2050, and declared that ‘Emission reduction to begin as soon as possible’. Many have criticised this as being ‘unambitious’, but these measures were not unanimously approved. Nine member states voted against the proposals.

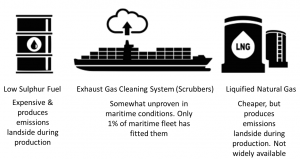

The more determined measure, however, is IMO2020. An initiative which will require Sulphur Oxide levels in ship’s exhaust gases to be reduced from a maximum of 3.5% to 0.5% effective January 1st 2020. To comply, ship operators have three options:

Freight rates are likely to increase regardless of the method used. At this stage, the major fuel oil suppliers are yet to release their pricing for low sulphur fuels but ships will need to be bunkering these oils from November in order to be compliant on January 1st.

So far, only 1% of ships has had Exhaust Scrubbers fitted, and the take-up is not likely to exceed 5% as retro-fitting is expensive and time-consuming.

The other principle measure to reduce fuel use has been in operation now for several years – Slow Steaming. By reducing speed by 10%, ships burn around 35% less fuel. A large container ship steaming at 22 knots burns up around 250 tonnes of fuel per day. Dropping the speed to 20 knots reduces fuel consumption to 175 tonnes per day. For the shipping lines, this is a win-win. Outside of capital costs, fuel is their largest expense – filling up a containership costs US$2Million and to reduce costs and reduce emissions at the same time enables them to improve their bottom line whilst boosting their green credentials.

Shipping lines operating on Asia-Europe routes use ‘Slow-Steaming on the inbound leg and ‘Super-slow steaming’ on the Outbound, where cargo volumes are much lower. The down-side to this is slower transit times, and some of the saving is offset by the need to use additional ships to maintain weekly services. However, ships are in plentiful supply.

Modern container ships are 40% more efficient than those deployed 10 years ago, with improved engines and propellers, and their huge size means the emissions per tonne/kilometre is much lower.

Train?

The other modern option available to shippers from Asia is the train service from Northern China through to Europe. Most of the trains terminate at either Duisburg, Germany or Warsaw, Poland, although there are less frequent trains to other destinations. Costs are lower than airfreight, considerably higher than sea, and it’s similar for emissions too. An 18 tonne air freight consignment from China to the UK would generate around 72 tonnes of carbon dioxide, and by train, just over 5 tonnes.